Comprehending the Principles of Welding Inspection to Ensure Quality and Safety And Security

In the world of contemporary engineering, welding inspection stands as a cornerstone for ensuring both the high quality and safety of structural developments. What are the subtleties of these inspection techniques that make them crucial for preserving architectural stability?

Relevance of Welding Inspection

In the world of commercial fabrication, the significance of welding inspection can not be overemphasized. Welding examination plays a vital role in making certain the stability, safety, and long life of bonded frameworks (Welding Inspection Madison).

The process of welding inherently entails intricate variables, consisting of temperature level, material buildings, and environmental problems, every one of which can influence the top quality of the weld. A thorough inspection identifies defects such as fractures, porosity, and incomplete fusion, which can endanger the strength and integrity of the weld. By identifying these issues early, corrective actions can be taken, thereby lowering the threat of failure and linked expenses.

Furthermore, welding assessment adds to regulatory conformity, as lots of industries are controlled by rigorous safety requirements and guidelines. Failing to stick to these policies can lead to lawful obligations and punitive damages. Eventually, welding inspection not just safeguards physical frameworks but also maintains and protects human lives industry track records.

Key Welding Evaluation Techniques

Although welding examination is crucial to guaranteeing the quality and safety of bonded frameworks, it is the details approaches used that figure out the efficiency of the examination procedure. Trick welding inspection methods can be broadly classified into non-destructive screening (NDT) and destructive testing. Non-destructive testing approaches such as aesthetic examination, ultrasonic screening, radiographic screening, magnetic fragment testing, and liquid penetrant testing are primarily utilized to examine the residential properties of a weld without creating damage. Aesthetic inspection is frequently the first step, entailing a detailed evaluation of the weld's surface for issues like cracks or porosity.

Magnetic particle screening and fluid penetrant screening are surface area inspection approaches utilized to find surface area and near-surface imperfections. These extensive inspection methods guarantee that welds meet industry requirements and safety requirements, therefore guaranteeing architectural honesty and efficiency.

Duty of Licensed Examiners

Certified assessors play a crucial role in the welding assessment procedure, guaranteeing that all welds adhere to rigid industry criteria and safety laws. Their proficiency is crucial in identifying flaws or irregularities that might jeopardize the structural integrity of a weld. By diligently analyzing each weld, certified assessors assist protect against possible failures that might result in pricey fixings or dangerous mishaps.

To end up being certified, inspectors have to undertake rigorous training and testing, which acquaints them with numerous welding strategies, materials, and screening approaches. This detailed understanding permits them to examine weld quality successfully and make educated judgments concerning their safety and security and integrity. Additionally, certified examiners excel in interpreting blueprints and specs, making sure that the welding job lines up with the project's style demands.

An integral part of their duty is to document their searchings for extensively, offering a detailed document of the inspection process. Their payment is indispensable in maintaining high degrees of quality and security in welding operations.

Tools Used in Welding Evaluation

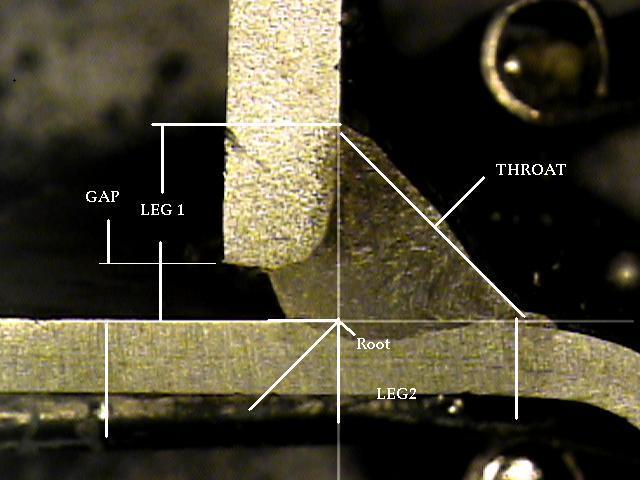

Welding assessors depend on a selection of specialized tools to execute their duties properly, making certain each weld fulfills the required have a peek here standards. Among these devices, visual examination help like multiplying glasses and mirrors are fundamental, enabling inspectors to very closely check out welds for surface problems such as cracks, porosity, and undercut. Calipers and fillet weld determines are crucial for determining weld dimensions to verify conformity with layout specifications.

Advanced tools extend past aesthetic help, including non-destructive testing (NDT) tools. Ultrasonic screening tools are pivotal in detecting subsurface defects, making use of acoustic waves Your Domain Name to reveal internal gaps without jeopardizing the weld's integrity. In a similar way, radiographic screening employs X-rays or gamma rays to capture photos of a weld's interior, highlighting prospective defects.

Magnetic fragment screening is an additional important device, especially for discovering surface area and near-surface suspensions in ferromagnetic products. By using magnetic fields and ferrous bits, inspectors can determine flaws that could or else be unnoticeable.

Dye penetrant evaluation is commonly used for non-ferrous products, supplying a contrast-enhanced aesthetic look for surface-breaking defects. Welding Inspection Madison. Together, these tools allow welding examiners to adequately analyze weld high quality, guaranteeing safety and reliability in various applications throughout sectors

Guaranteeing Architectural Honesty

Welding procedures have to follow well-known requirements and codes, such as those defined by the American Welding Culture (AWS) or the International Company for Standardization (ISO) These guidelines guarantee that the welds can hold up against operational tensions and ecological variables. Certified and accredited welders play a crucial function in this process, as their proficiency ensures that techniques are applied properly, minimizing flaws such as fractures, porosity, and insufficient fusion.

Post-weld inspection is an additional essential part of verifying architectural honesty. These inspections validate that the welds Learn More fulfill the required top quality requirements, providing guarantee of their resilience and integrity.

Conclusion

The fundamentals of welding examination are necessary for maintaining the high quality and safety of welded frameworks. By executing vital evaluation approaches, such as aesthetic analyses and non-destructive testing, possible problems that could endanger architectural integrity are determined. Qualified assessors are vital in ensuring conformity with sector requirements and efficient communication amongst stakeholders. The use of specialized tools additionally enhances the examination procedure, inevitably safeguarding human lives and prolonging the life-span of welded building and constructions.

Welding evaluation plays an important role in ensuring the integrity, safety and security, and durability of bonded frameworks.Although welding assessment is vital to making sure the high quality and safety of welded structures, it is the certain techniques utilized that determine the effectiveness of the inspection process. Key welding examination techniques can be generally classified right into non-destructive screening (NDT) and harmful testing.Certified examiners play a crucial duty in the welding inspection procedure, guaranteeing that all welds abide with rigid market criteria and safety policies.The basics of welding examination are necessary for keeping the quality and safety and security of bonded structures.